We get your priorities!

Start a conversation with one of our engineers to discover a way forward.

Contact UsWhether you’re exploring, drilling, transporting, or refining—you face daily pressures to improve efficiency, perform under harsh conditions, maintain safety, and keep costs under control. Whether you’re facing the extreme temperatures of an offshore rig, fighting the extreme pressures on the ocean floor, or accommodating the world’s most corrosive environments, there’s no room for error—and no time for repairs. When new materials and new thinking are involved in meeting these conditions, our team has a 30-year track record in Oil & Gas.

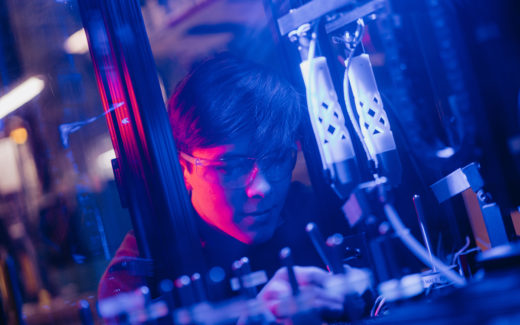

We develop new products (and reimagine conventional ones) for oil and gas components such as bellows, compensators, accumulators, high pressure seals, and more. We design for extremes of temperature, pressure, and corrosive environments—especially when high lifecycle, zero leakage, maintenance-free operation, and high performance are essential. Our process is fast and efficient, with full in-house resources, including: 3D solid modeling (rapid proof-of-concept), finite-element structural analysis, flow simulation and sizing—along with all required qualification and documentation to meet global performance standards.

We bring our innovative designs to life in an advanced manufacturing facility where state-of-the-industry processes are executed under the highest standards. Seasoned technicians supervise advanced fabrication in:

Start a conversation with one of our engineers to discover a way forward.

Contact UsTraditional elastomer-based seals could not be used by our customer, a large manufacturer of gas turbines, due to their inability to withstand the high temperature environment.

Read Case StudyAs our customer’s rigs ventured further off shore, their equipment experienced significantly higher differential pressures. One of the critical components, gas lift valves, were facing differential pressures in the 10,000 psig range.

Read Case Study