We get your priorities!

Start a conversation with one of our engineers to discover a way forward.

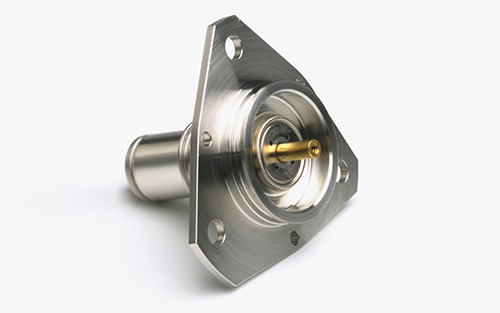

Contact UsHigh-performance thermal actuator for aircraft engine manufacturer changes everything.

The legacy design for a thermal actuator—being used by a large commercial aircraft engine manufacturer on the fuel-oil heat exchanger—relied upon an elastomer-encased wax medium. Unfortunately operating temperature extremes rapidly degraded the elastomer, resulting in a very high rate of failure for this device.

Senior Metal Bellows took a different approach, designing a new thermal actuator that used a welded metal bellows to encapsulate the wax. This provided the necessary compliance for actuation, while significantly increasing the life cycle of the actuator and virtually eliminating the failures that had previously plagued the company.

Cycle life increased by more than 10x, service life extended from 1 year to 10 years, all-metal construction eliminated performance creep; due to wax leakage, metal bellows is impervious to temperature extremes.

Start a conversation with one of our engineers to discover a way forward.

Contact Us